By DONALD S. KLINE Solid black gold: Illinois' coal and America's energy-economy-ecology dilemma ON A CLEAR DAY, if you look

carefully south from the State Capitol in Springfield you can see the twin, 500-foot stacks of the Kincaid power plant

of Commonwealth Edison. The stacks

and the plant are, in many ways, symbols of what The New York Times

called America's "energy-economy-ecology" (EEE) dilemma. A problem of systems But there are problems. U.S. production of crude oil topped out in 1970 and

has been declining since. As energy demand increased during the 1960's, the necessary increase in oil imports gave

the oil exporting nations (OPEC) an

increased share of power in the global

market place. Thus, the 1973 embargo

and the establishment of the oil cartel

has resulted in an historically unprecedented, massive shift of wealth from the

United States, Japan and Western

Europe to the oil exporters. The World

Bank estimates that, at current prices,

the cumulative wealth shift will amount

to hundreds of billions of dollars by

1980. Since this massive outflow could not

be tolerated by our present financial

system, "Project Independence" was

articulated by President Nixon as a

necessary solution. The notion of independence from Mideast oil sources

has been further pursued by President

Ford in his 1975 economic messages. The short-term solution to the high

cost of foreign oil lies in (1) the rapid

development of existing domestic coal

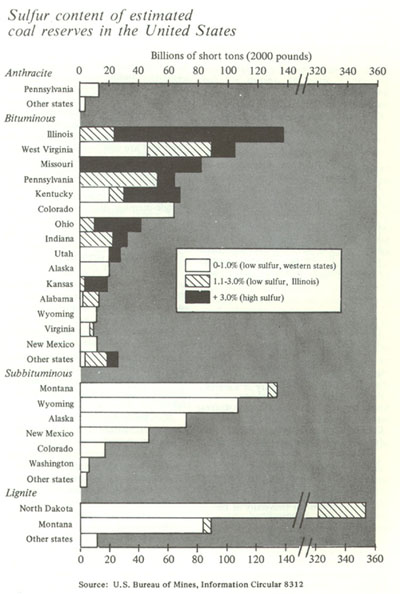

reserves and (2) a stimulus to U.S. offshore explorations for oil and gas. Obviously, the former is of greatest concern for Illinois. Coal in Illinois Coal deposits vary in quality from

high energy anthracite to low energy

lignite with the varieties of bituminous

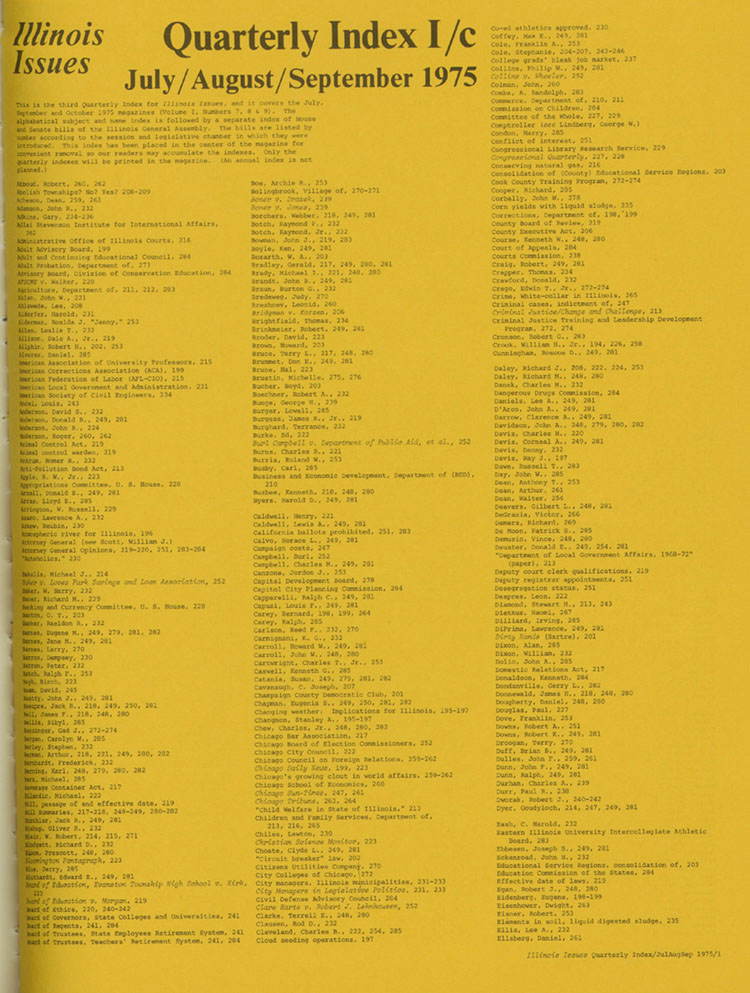

in between. As the table shows, lower

energy coal (sub-bituminous and

lignite) tends to be located in the states west of the Mississippi and high energy

coal (anthracite and bituminous) in the

states east of the Mississippi. Since

the area of greatest industrial activity

in the United States lies east of the

Mississippi, this situation would appear favorable. But much of the high

energy coal in the East contains high

percentages of sulfur (see the chart on

page 305), and sulfur is just what

federal and state environmental officials say must not be released into the

atmosphere in large quantities. Eastern

industry then needs low sulfur Western

coal, but these industries obviously are

not pleased with the coal's relatively

low energy content, not to speak of the

transportation costs involved. Currently, alternative solutions to

this problem are complicated by two

factors. First, on June 1, 1975, new air

pollution standards went into effect. Second, a strip-mining bill, passed by

Congress for the second time, was

vetoed by President Ford for the second

time. On June 10, 1975, the House of

Representatives failed to override the

President's veto by three votes. Taking into account these two constraints, some of the alternative solutions to the EEE dilemma may be viewed as short-term and temporary.

Low sulfur coal can be imported, at a

high cost, from Montana. High sulfur

Illinois coal can be "washed," to a

degree to remove sulfur, before it is

burned. Stacks can be built, at great expense, to the 800-foot level in order to

dissipate emissions over a wider area.

Other solutions are longer term and

even higher in cost. Gas scrubbers can

be installed. High sulfur coal can be

gasified or liquified at the mine mouth. Illinois coal is high sulfur 302 / Illinois Issues / October 1975

Associate professor of administration at

Sangamon State University, he has degrees

in business. Foreign trade, and social

science. Kline recently taught a course

dealing with the national and global energy

situation.

There is a growing awareness and, indeed, consensus among decisionmakers in both public and private organizations that the reductionist,

fragmented way of viewing the world,

people and problems will not do for the

1980's. In the last four years there has

been a shift in values in our society from

what scholar George Cabot Lodge calls

"scientific specialization and fragmentation" to "a new consciousness of the

interrelatedness of all things." In applying this systems approach, if one takes

the long view of the solution to energy

dilemma of the United States, the inevitable answer is atomic fusion power

and solar power. These are 21st century

solutions. I and many of you reading

this will probably be dead by then. But

how do we cope with energy demands of

the next five or twenty-five years? In the

short run, it appears that we will have to

rely on some uncertain combinations of

oil, gas, and—most important—coal.

In 1973 coal production in the United

States was just under 60 million tons.

Of this, some 380 million tons came

from just four states: Kentucky (127

million tons). West Virginia (115),

Pennsylvania (77) and Illinois (62). But,

future coal production comes from present estimated reserves. The table shows

coal reserves, defined as coal in seams

more than 28 inches thick if located

deeper than 150 feet and in seams more

than 18 inches if located 150 feet deep

or less.

Most of Illinois' vast bituminous

reserves have a high sulfur content. As

noted above, high energy coals seem to

be high sulfur coals and vice versa. The

The short-term solution to the energy crisis may be coal, and Illinois has 140 billion tons in reserve near the nation's industries. But, there is a dilemma. Examine the case of Kincaid power plant and Peabody # 10 mine

energy demands of the country are

often in conflict with its environmental

requirements, but never more so than in

the matter of coal. When the Clean Air

Act of 1972 was partially implemented

in June of this year, high sulfur coal

could still be mined at Peabody Coal

Company's # 10 mine just west of the

Kincaid plant, but could not be burned

at the plant. What can the State of

Illinois and Commonwealth Edison do

about this perplexing situation? Kincaid fossil fuel plant Kincaid, like all fossil fuel plants,

generates large amounts of ash. Bottom

ash is easily and periodically shoveled

out of the boilers. Airborne fly ash is a

different problem. All coal fired units

have installed electrostatic precipitators

which act as giant magnets in attracting ash particles. These devices remove 98 per cent of the fly ash. In newer installations the precipitators are above 99 per cent effective. Coal-burning plants like Kincaid also face the problem of sulfur oxide

emissions. Different grades of coal contain varying amounts of sulfur, as the

chart shows. Some plants have switched

to lower sulfur Western U.S. coal; others have installed gas-stack

"scrubbers." Another similarity of Kincaid and all

fossil plants is their balanced draft

boiler operations. OSHA (Occupational Safety and Health Act)

legislation required these improvements to eliminate gases from the boiler

room. This is an obvious gain in plant

safety. The Kincaid plant is also unique in

several respects. First, Kincaid serves as

a link to other regional U.S. electric

power generating systems within

MAIN (Mid-America Interconnected

Network). The plant was built to and

stands ready to handle excess energy demand from the South and East

(American Electric Power system), the

West (St. Louis system), and from the

North (Commonwealth Edison). Second, Kincaid gets its entire supply

of coal from the Peabody Coal Company # 10 mine located just a few miles

to the west. This mine is the largest in

the world in terms of total tonnage

taken out of one hole. By early 1974,

after 23 years of operation, 100 million

tons of coal had been mined. The

average seam thickness is six feet and

the depth of the mine below ground surface averages 300 feet. The length of the

mine is 12 miles, and a 30-mile continuous conveyor belt allows direct

movement of the coal from the mine to

the Kincaid plant. The recovery rate of

coal at Peabody is 52 per cent (compared with about 75 per cent in the strip

mining operations of the West), but the

remaining coal could be recovered via

coal gasification at the mine mouth.

Within the last six months a "Serpentix" system has been installed to allow

the direct transfer of coal from the mine

The case for or against coal can be

clarified by examining the specific case

of the Kincaid power plant and the

nearby Peabody Coal Company # 10 mine. It is necessary to look at the Kincaid plant in greater detail, both in

terms of its similarities to and

differences from other fossil fuel plants

within the Commonwealth Edison

system. Consider the similarities.

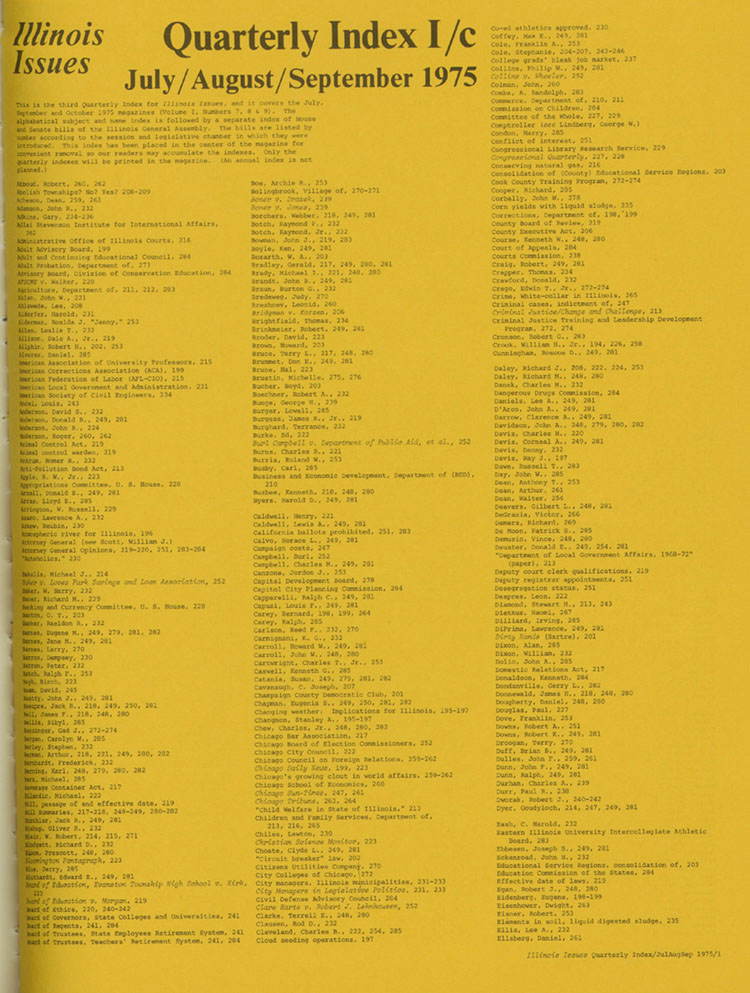

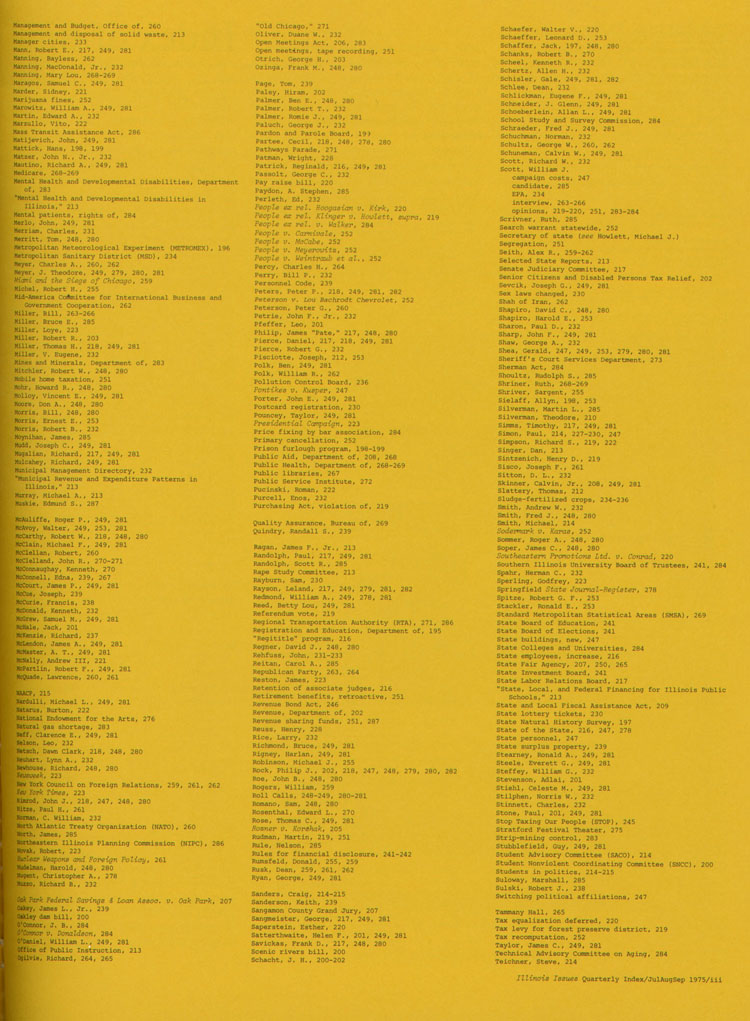

Coal reserves by thirteen leading states by energy category, estimated 1965 (Billion short tons—2,000 pounds)

|

Western |

Anthracite |

Bituminous |

Sub- |

Lignite |

Total |

|

North Dakota |

— |

— |

— |

351 |

351 |

|

Montana |

— |

79 |

132 |

87 |

298 |

|

Wyoming |

— |

13 |

108 |

— |

121 |

|

Alaska |

2 |

21 |

71 |

— |

94 |

|

Colorado |

— |

62 |

18 |

— |

80 |

|

Missouri |

— |

79 |

— |

— |

79 |

|

New Mexico |

— |

11 |

51 |

— |

62 |

|

% of U.S. |

2 13% |

265 36% |

380 98% |

438 98% |

1,085 69% |

|

Eastern |

|

||||

|

Illinois |

— |

140 |

— |

— |

140 |

|

West Virginia |

— |

103 |

— |

— |

103 |

|

Pennsylvania |

12 |

58 |

— |

— |

70 |

|

Kentucky |

— |

66 |

— |

— |

66 |

|

Ohio |

— |

42 |

— |

— |

42 |

|

Indiana |

— |

35 |

— |

— |

35 |

|

% of U.S. |

12 80% |

444 61% |

— —% |

— —% |

456 29% |

|

Thirteen states |

14 |

709 |

380 |

438 |

1,541 |

|

% of U.S. |

93% |

97% |

98 % |

98%, |

98 % |

|

TOTAL U.S. |

15 |

729 |

388 |

448 |

1,580 |

SOURCE: National Air Pollution Control Administration Pub. No., AP-52, 1969.

October 1975 / Illinois Issues / 303

Coal-fired plants will have to meet federal standards on sulfur oxide emissions. Their choice is between importing low sulfur, low energy coal from the West or using Eastern high sulfur, high energy coal, but only after investing in a method to decrease the sulfur

face to the continuous conveyor. Such a

system can now move coal around right

angles within the mine, something not

possible before the "Serpentix" installation. The Kincaid plant uses some four

million tons of high (about 4.2 per cent)

sulfur, bituminous coal a year from the

mine. This unique marriage of Kincaid

and Peabody # 10 provides some insulation against the need to import Western

coal if' (a) Kincaid receives a continuance of its emissions variance

already granted by both federal and

state environmental protection agencies, or (b) a coal gasification process

can be installed. Third, the function of the Kincaid

plant is to "bulk transmit" electricity

out of its own generating area. Other

fossil plants in the Commonwealth

systems were built in the areas they

serve (e.g. the Powerton plant at Pekin).

The Kincaid plant was built in 1967 at a

cost of about $145 million, specifically

to tie into the MAIN system. Because

of this, extra miles of high voltage

transmission lines had to be

erected—345,000 volt lines into the

MAIN network and 765,000 volt lines

feeding into other transmission systems.

Because so many other areas are dependent on Kincaid's power, it illustrates

perfectly Lodge's point about "the interrelatedness of all things." Finally, the Kincaid plant has its own

cooling lake—Lake Sangchris. There are no easy solutions The Kincaid plant is the only fossil

plant in the Commonwealth system

which does not at present "wash" coal

burned to reduce sulfur content. Early

in 1975, the company obtained a

"variance" to operate the Kincaid plant

in the face of new sulfur oxide emission

standards coming into effect in June. By

the spring of 1976, it is planned that all

coal from Peabody # 10 burned at Kincaid will be "washed." This will reduce

the sulfur content by 0.6 to 0.8 of one

per cent—close to the maximum permissible level under the new legislation. Five courses to follow Course of action No. 1 means that,

as, the chart shows, much of Illinois

bituminous coal cannot be burned and

low sulfur coal must be imported at

high cost. People in Illinois get clean

air. What do people in Montana get?

Here is the essential and crucial nature

of a systems approach to the problem.

Strategic decisions must be made which

optimize benefits to society as a whole.

The strip mining of Western coal for the

benefit of Eastern states would have an

unknown but significant impact on the

fragile ecology of the great prairie

states. The second veto of the strip mining bill by President Ford recently—he said we need the coal—may very well'

result in Congress passing an even

stronger bill by a margin that is veto-proof. The great argument was over

how much coal production would be

lost if the bill were passed. No one can

know that. At this time, there are no

plans to import Western coal for burning in the Kincaid plant. At present

rates Peabody can produce coal steadily

until 2070 A.D. Course of action No. 2, "washing,"

as mentioned above, is to be implemented by spring of 1976. It is a solution which is uniquely suited to Kincaid.

Peabody coal will still be shuttled by

conveyor directly from the mine to the

boilers, but it will be washed en route.

However, "washing" coal will take

large amounts of water, water which,

starting in 1980 may be supplied by

Lake Springfield II, presently in the

planning stage. Furthermore, there are

problems of potential water pollution

and solid waste disposal with regard to

the large amounts of toxic substances

which would be "washed" out of the

coal. Course of action No. 3, 800-foot

stacks, may appear to be the best solution, but in reality it only substitutes

one problem for another. Pushing the

sulfur oxide emissions to very high

altitudes by the use of these tall stacks

merely removes the pollutants from one

small geographic area (Springfield) to

another (depending upon prevailing

winds—Eastern Illinois, Indiana,

Northern Kentucky). This course of action may permit the burning of Peabody

high sulfur coal and therefore aid the

economy of the state by providing

energy. This is the benefit, but the

systems approach to the EEE dilemma

requires that the cost to other parts of

the system be considered as well as the

costs to society as a whole. A few years

ago, when Apollo astronauts flew over

the United States they commented that

large parts of the entire Colorado

plateau were hidden not by nature's

clouds but by man's smog. One explanation for the smog was the burning

of coal in huge thermal generating

plants in the Four Corners section of

the Southwest to furnish electricity to

the Los Angeles basin. Los Angeles had

earlier decided that it did not want the

pollutants in its air. In the finite system

of our planet—referred to as Spaceship

Earth—one of the basic laws of ecology

is that "everything has to go somewhere." 304 / Illinois Issues / October 1975

The federal EPA has established

desired air standards for sulfur oxide

emissions at two levels: (1) primary

standards to protect public health at .03

parts per sulfur oxide for one million

parts of air: and (2) secondary standards to protect public welfare at .02

parts of sulfur oxide per one million

parts air. The "health" standard of .03 parts per million went into effect on

June 1, 1975. This controls 90 per cent

of all sulfur oxide emissions.

Given the new federal emission standards, there are basically five courses of

action for coal-fired plants: (1) burn low

sulfur (less than 1 per cent content); import low energy coal from the Western

states; (2) "wash" Illinois high sulfur

coal to reduce sulfur content; (3) go to

intermittent control systems of tall

(over 800-foot) stacks; (4) rapidly install costly gas "scrubbers"; (5) remove

sulfur by a "front-end" process of coal

gasification or liquefaction (conversion

to low sulfur oil).

Course of action No. 4. the "gas scrubber, "is currently a source of great controversy. The federal EPA has slated that "gas scrubbers" are the "most immediately promising control system for sulfur dioxide." The issue is, like most today, technically complex. First, chemicals such as calcium sulfate and calcium sulfite are formed in the scrubbing or washing process. These "outputs" of the process plug spray nozzles and valves and every few days must be removed by high pressure hoses or even a man with a hammer. In some extreme cases plant shutdowns are required. Second, sludge byproducts must be disposed of. This sludge contains high concentrations of sulfur and there is a strong probability that it will seep from the disposal beds into underlying water tables. Also, shipping sludge from urban areas is quite costly. Thus, air pollution could be—given unknown lag times—converted into dangerous water pollution. The question of the gas scrubber also arose in a controversy between City Water Light and Power (CWLP) in Springfield and the Illinois EPA over the construction of the Dallman III fossil fuel plant. One difference between CWLP and Commonwealth Edison is that, by Illinois law. publicly owned utilities like CWLP can burn only Illinois coal.

|

Still other problems Course of action No. 5, gasification or liquefaction, appears to be no better and may even be far worse depending on what kind of coal or lignite is gasified or liquified at which location. One obvious possibility is to gasify the subbituminous and lignite at the mine mouth in Montana and Wyoming. Two ecological problems emerge. The first is the devastation to the fragile lands mentioned earlier. Secondly, massive amounts of water are required for the gasification or liquefaction process. The water needed for a network of, say 50 of these plants, would very rapidly begin to compete with the agricultural water needs of the vast Western wheatlands. Further, as the water is circulated through the degasification system it too has to be purified or else it will rapidly contribute to water pollution in those lands. On the other hand if the "frontend" gasification of liquefacfion process were to take place in Illinois, the water requirements could be more easily met. There are many other problems surrounding the FEE dilemma not the least of which is capital financing. In February 1975, Commonwealth Edison announced cancellation of plans to build coal gasification facilities at both the Powerton (Pekin) and Kincaid stations. To attach gasification systems to the four generating stations at the two sites would cost $1.7 billion—three limes the estimated cost of a year earlier. Said James Fancher, director of air quality for Commonwealth Edison, "We still believe large scale coal gasification will prove to be technically and economically feasible if time is allowed for its orderly development. But it is clear that installing such systems on a crash basis during early stages of the technology would not be prudent." Mr. F.E. "Bud" Stauffer, superintendent of the Kincaid station, concurred, saying, "Gasifiers are not far enough along to process soft coal—a lot has to be learned." |

|

October 1975 / Illinois Issues / 305