By SUE KENNEDY

Formerly a county government reporter

for the Illinois Stale Register, she

writes a monthly education newspaper

for the Illinois Office of Education.

The coal boom has a big bite: Gas plants would produce needed fuel but consume water and farmland

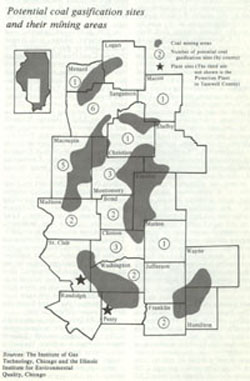

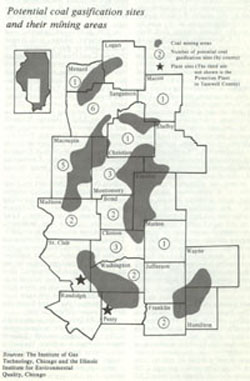

The coal gasification

industry is on the move in

Illinois with over 29 sites

for converting coal to

natural gas and crude oil.

Backed by federal, state

and private funds, three

demonstration plants are

planned: New Athens,

Powerton and Perry

County, but hard

allocation choices lie

ahead — one commercial

plant uses 14 to 28 million

gallons of water daily and

creates 5,000 tons of waste

IN TEN YEARS, the nation's supply of natural gas will be almost gone, but

there is a substitute and there is plenty of

it in Illinois. The state's high sulfur coal

can be converted, by an expensive and

complex technology, into a substitute

for the nation's dwindling supply of

natural gas.

In Illinois, there are three coal gasification facilities scheduled which will

make the state the national leader in

the new industry. The New Athens (St.

Clair County) and the Perry County

plants will be constructed, and a third

will be the existing Powerton Plant near

Pekin which will be converted to the

new industry. See the accompanying

map for the 29 potential coal conversion

sites in Illinois. Such an industry would

require an extractable coal reserve of

150 million tons per site, which is the

amount needed to supply a gasification

plant over its 20-year lifetime. Each of

these plants would require a mine

complex producing about six million

tons of coal per year, and each plant

would produce 250 million cubic feet of

substitute natural gas each day. A

1974 study by the Illinois Institute for

Environmental Quality (IIEQ) identified five sites for commercial-size plants,

besides the St. Clair County site — two

in Fayette County, one in Franklin

County, one in Washington County,

and one on the Macoupin-Madison

county line.

Vast coal reserves

Illinois is second only to Montana in

measured coal reserves. Most of it is a

highly sulfurous, bituminous variety

which cannot be burned without

measures to reduce sulfur dioxide

emission into the atmosphere. Sixty-five

per cent of the state (86 counties)

contains coal deposits totaling

approximately 161 billion tons. About

14 per cent of these reserves is found in seams lying less than 150 feet deep,

according to a 1974 Illinois State

Geological Survey report. But Illinois

must provide more than its coal if it

wishes to establish a sizable coal gasification industry in the state. A sizable

chunk of Illinois land and water resources, some of them irreplaceable,

must also be committed if industry is to

be attracted to the state.

The conversion process

Balking at the cost of installing stack

gas scrubbers to eliminate sulfur dioxide

after burning, industry nationwide is

turning to coal conversion. "You name a

major oil company, and they've got a big

budget going for coal gasification, and

each thinks they've got the best

process," said Jack Howard, manager of

coal development in the Illinois

Department of Business and Economic

Development (BED).

The conversion process itself is

relatively simple, although there are as

many variations as there are companies

involved. Basically, coal is heated in the

presence of steam which causes some of

the hydrogen in the steam to unite with

the carbon in coal. This forms methane

(CH4), the principal ingredient of

natural gas. Besides producing

methane, the process also generates

carbon monoxide and hydrogen. These

two gases can be made to react to form

more methane in a step called methanation.

During the gasification process, some

of the carbon is burned in the presence

of air (O2) to produce the heat that

makes the process work. This burning

yields carbon dioxide as a waste product

as well as ash and sulfur which can be

sold or stored. To get a high quality gas

the oxygen content in the gasifier is

increased, yielding a higher percentage

of methane. In liquefaction, coal is

heated to produce gas which then reacts

16 / November 1976 / Illinois Issues

under pressure with hydrogen to

produce a liquid plus leftover char.

Industry's desire to scale this process to

modern needs has spawned a profusion

of pilot and demonstration plants all

over the country in the past few years.

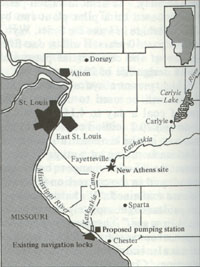

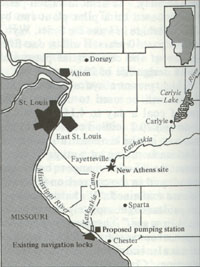

Illinois' first major coal conversion

plant will combine the technologies

of gasification and liquefaction to produce a high quality synthetic natural

gas (SNG) that can be burned in homes

and a low sulfur fuel for industrial use

and liquid products. It will be located

on 2,000 acres between New Athens

and Fayetteville in the Kaskaskia River

Valley in southeastern St. Clair County,

approximately 30 miles southeast of St.

Louis. BED'S site proposal for the

Coalcon project listed assets of the area

including the existence of 1.6 billion

tons of mapped coal reserves within the

six township area surrounding the site

— an amount which could provide

"seven times the estimated 110 million

tons required by the commercial plant

over a 20-year period."

New Athens demonstration plant

Initially, the plant will be a demonstration model and will be purchased by

Coalcon at the end of three years of

testing. The federal Energy Research

and Development Administration

(ERDA) awarded the contract to Coalcon, a partnership since 1974 between

Union Carbide Corporation and Chemical Construction Corporation (a unit of

General Tire's Aerojet-General

Corporation), and announced the site

selection last November after examining

17 other sites in five states (Ohio,

Pennsylvania, West Virginia, Kentucky

and Indiana). The demonstration plant

is to be based on a pilot plant run by

Union Carbide in Lake DeSmet, Wyo.,

over the past 10 years. It will be one-fifth

the size of the commercial plant and

have a design life of 20 years.

|

A high pressure hydrocarbonization

process will be used to convert 3,850

tons of coal a day to 4,142 barrels of

liquid and 20.2 million cubic feet of gas

products in the demonstration phase.

"Coalcon is taking advantage of coal's

natural tendency to change to both a gas

and a liquid in the conversion process,"

Howard explained. "It's harder to drive

the substance completely to either a

liquid or a gas." The greatest potential

from coal conversion in Illinois is a coal

chemicals industry, Howard said,

reflecting Coalcon's focus on the liquefaction process. "Many products

which were made from crude oil when it

was cheap can be made from coal." Fuel

oil and chemicals such as ammonia and

naphthalene will be produced at the

New Athens plant.

The sulfur produced in the process

will be sold to make sulfuric acid, if

possible. If it cannot be sold, the

material will be given away or stored

until it can be marketed. The ash yield,

to be buried on the site, will be about 10

per cent of the total coal processed daily,

or about 385 tons if 3,850 tons of coal are used. Besides coal supplies, other

resources are needed to operate a

gasification plant, and Coalcon

executives believe those resources are

available at the New Athens site. Nearly

2 million gallons of water, 80 per cent

of which is totally consumed in the

process, will be withdrawn daily from

the nearby Kaskaskia River in the first

phase. About 21 million gallons of

water will be withdrawn for the com-

mercial plant. Should supplies run low,

a prospect designers say is unlikely,

plans are being made to pumpadditional water from the Mississippi River.

|

|

November 1976 / Illinois Issues / 17

Specific state incentives proposed for the New Athens

plant include water at no charge during the life

of the demonstration project, cheap

river frontage., extension of roads at no cost

and a 5-10 year property tax break on leased lands

Electricity to run the plant will be supplied by the nearby Baldwin power

plant. Transportation in the area includes the Illinois Central Gulf Railroad, U.S. Route 460, Illinois Route 13,

and various natural gas and refined

products pipelines passing close by the

site. Also, barge service with the ability

to transport up to 20 million tons of coal

per year will be available on the

Kaskaskia River following completion

of the navigation channel in 1978.

Finally, the metropolitan St. Louis area

will provide the sizable construction,

maintenance and operation crew.

The only real concerns with the site

involve possible environmental

problems in the future, according to

proposal writers. "A well controlled

coal conversion demonstration facility

would not contribute sufficient particles

and sulfur dioxide (to the atmosphere)

to exceed the allowable increments.

However, a commercial plant may

create some problems because of its

size." An environmental impact

statement on the project remains to be

done, although Coalcon completed an

environmental assessment as part of

selection criteria imposed by ERDA.

The design phase is expected to take 18

months and cost $17 million.

Construction is planned to start in 1977

with plant operation in 1980. The commercial plant is expected to be in operation by 1985.

Perry County and Powerton sites

The Perry County coal conversion

facility, which will also employ

liquefaction and gasification

technologies, will be located

approximately 11 miles southwest of

Pinckneyville. In its demonstration

phase it will produce 22 million cubic

feet of pipeline quality gas and 2,000

barrels of crude oil per day from 2,300 tons of coal. Water will be piped from

the Mississippi River, along a

previously obtained, 17-mile right-of-way.

A $20 million engineering and

development phase will begin

immediately in Perry County. The

Illinois Coa1 Gasification Group

(ICGG), a consortium among Northern

Illinois Gas Company, Aurora; People's

Gas Light & Coke Company, Chicago; Central Illinois Public Service

Company, Springfield; Central Illinois

Light Company, Peoria, and North

Shore Gas Company, Waukegan, was

selected by ERDA (Energy Research

and Development Administration) this

summer to build the facility.

Construction on the demonstration

plant will begin in 1978 if Congress

approves the funding. Commercial

plant construction will begin around

1985.

Both the New Athens and the Perry

County sites are nearly perfect locations

for a coal conversion facility according

to BED Manager of Program

Development Rusty Glen. Land

(previously stripped and reclaimed),

water and coal are all readily available.

The companies which will provide much

of the coal for plant operation also own

all the land needed for the facilities.

"This makes it much easier than having

to deal with several landowners," Glen

says. About 65 per cent of the coal to be

used in each facility will be taken from

nearby mines. The rest will come from

various parts of the United States and

Europe, to test different grades.

Lastly, ERDA gave the go-ahead this

summer for an on-site coal conversion

facility at Commonwealth Edison's

Powerton Plant near Pekin. The facility

will produce boiler fuel for use in the

electric generating plant.

Although industry has done its part to

bring coal conversion to Illinois, government has also aided the project

ERDA is financing the New Athens

plant to the tune of approximately $110

million while Coalcon is sinking around

$100 million into it, and the state of

Illinois will contribute S25 million from

coal development bonds.

|

ERDA will finance approximately 50

per cent of the $276 million Perry

County project and the $105 million

Powerton facility. The State of Illinois

will contribute $7.2 million to the

Powerton facility, and Commonwealth

Edison will pick up the balance. ICGG

presently plans to spend around $130

million on the Perry County plant.

Illinois' share has not yet been

determined, but could be around 10 per

cent of the iota! project cost.

The Coal Development Bond Act

A string of state legislation passed in

recent years has made possible the

financial backing of coal conversion in

Illinois. The Illinois Coal Development

Bond Act (P.A. 78-1 122). which passed

in 1974, provides $70 million from the

sale of bonds for financing a state

research, development and demonstration program primarily in coal. BED

(Illinois Department, of Business and

Economic Development) was granted

extensive powers of eminent domain to

acquire property, mineral or water

rights for the development of such

resources. And, an advisory council

composed of the governor, lieutenant

governor and heads of resource

concerned state agencies was created to

|

|

18 / November 1976 / Illinois Issues

advise the BED. Principal sponsor of the legislation was Sen. Bradley M. Glass (R., Northbrook).

At the same time, former Rep. Robert W. Blair (R., Park Forest), steered legislation through the General Assembly to create the Illinois Energy Resources Commission, composed of legislators and private citizens. In addition to recommending strategies for solving energy related problems in Illinois, the commission authorizes the issuance and sale of bonds for coal

development projects it deems worthy.

The state commitment to coal development

is firmly established. However,

in the 1975 legislative session, the idea

was expressed that perhaps the powers

of eminent domain extended to the BED

in the Illinois Coal Development Act

were a bit too broad. Since the law had

been enacted to give industry the incentive to develop coal resources,

many thought it was not proper to give a

state agency the power to condemn

private land for private use. P. A. 79-713, sponsored by Rep. John S. Matijevich (D., North Chicago), amends the

Coal Development Bond Act stating

that the BED'S power of condemnation

be exercised "solely for the purposes of

siting and; or rights of way and or

easements appurtenant to coal utilization and / or coal conversion projects". Another bill. H.B. 1704, sponsored by

Rep. Adeline Jay Geo-Karis (R,. Zion),

was passed to amend the Illinois Coal

Development Bond Act to provide for

the development of other energy

sources, but it was vetoed by Gov. Dan

Walker.

Specific governmental incentives

In addition, to help make Illinois'

high sulfur coal a bit more "usable"

while coal conversion techniques are

refined, Rep, Richard 0. Hart's (D.,

Benton) legislation (P.A. 79-1099)

directs the Illinois Pollution Control

Board to set regulations for "internment control systems." The measure

allows industries in low pollution areas

to burn high sulfur coal as long as sulfur

dioxide emissions do not exceed the

minimums set by law. An intermittent

control system entails selling up sensors

around a plain to monitor emissions.

|

|

Specific governmental (state and

local) incentives included in the BED'S

site proposal for the New Athens project

offered industry;

- water at no charge during the life of the demonstration project by virtue of

state-owned land adjacent to the Kaskaskia River.

- lease frontage on the river for water

intakes and discharge flumes from the

state at an annual cost of S!0 per foot of

river frontage and S75 an acre of backland;

- extension of county roads to state highways at no cost;

- a tentative 5-to-10-year property tax

moratorium for lands leased by the

state (The county government also

indicated there is wide discretion on

valuation of the leasehold.);

- the use of BED'S powers of eminent

domain.

The proposal also noted BED s

efforts to establish a U.S. Bureau of

Mines research station at Carbondale,

one of five in the country, for the study

of coal mining and reclamation problems A Coal Extraction and Utilization

Resource Center also exists at Southern

Illinois University at Carbondale for

this purpose. Also. the proposal states that three southern Illinois colleges have programs to "train, retrain or upgrade workers for Illinois mines. .

The impact of such an industry in several areas of Illinois would drastically affect not only the geography of the state, but its inhabitants as well. Water rights and loss of agricultural

land are just two of the issues that will

face Illinois citizens in counties where

future plants are being considered. At least one community action group

concerned about the growth of the coal conversion industry in the state. According to members to the Illinois South Project, based in Carterville, the question that Illinois citizens need to ask regarding this new industry is: "Who will benefit from coal and energy development projects, and who will pay the long-term costs?" Project member Dave Ostendorf acknowledges that the coal gasification industry may bring

certain benefits to the state and nation,

but only if its growth is managed so as to

have the least possible adverse effect on

the environmental and economic bases

of the states involved.

Tax costs

For starters, Ostendorf says citizens

should be aware of the tax impact of any

new plants on the community. For

example, the 5-to-10-year tentative

property tax moratorium originally

offered by St. Clair County for lands

leased by the state to Coalcon could put

a heavy burden on New Athens taxpayers, he says. Community residents

would have to bear costs for an array of

municipal services for the large number

of newcomers the plant is expected to

bring. "It is imperative," Ostendorf said, "that any preferential treatment extended to industry does not result in an

additional tax burden on residents of the community."

Ostendorf also points out that a

commercial size coal conversion plant

would require between 10,000 and

20 000 gallons of water per minute to operate. Between 14.4 and 28.8 million gallons per day would be entirely

consumed in the process. The Illinois Water Survey has already identified 240 potential sites for gasification related

reservoirs, according to Ostendorf. "Even if the water base were there," he said, "Illinois does not have a water permit statute that would control the rate and amount of water withdrawn from a natural watercourse or from groundwater or diffused water sources." Ostendorf said that the Illinois Economic and Fiscal Commission (a legislative study commission) made clear in Water Resources Management in Illinois: A Program Review (1974) that Illinois water rights law is largely an archaic and jumbled system of case law rather than

November 1976 / Illinois Issues / 19

Loss of farmland might be reduced by deep milling,

but the coal gasification industry could

play havoc with Illinois' water supply unless

water laws are changed and more reservoirs built

statutes, and that the system is heavily

based on riparian rights which allow an

owner of land adjoining a naturally

flowing stream to use water at his own

discretion. The report states that "it is

still private ownership of riparian land

which generates the recognized right to

use water, and not consideration of

social and economic impact."

Water supply

In regard to water supply, the commission's report stated, "There is still

enough water in the state to meet

current overall demand projections. A

number of things could happen, however, which would change the situation

dramatically. Two of the most important would be a substantial drought and

the widespread use of coal gasification."

The report adds that within 50 years,

regardless of either impact, water supply

problems can be expected in La Salle-Peru, Springfield, Carbondale, East

Moline and Cook County. Ostendorf

added, "The issue, it seems, is relatively

simple: unless Illinois enacts a water

permit statute or clearly delineates legal

definitions of how much water can be

withdrawn from a natural source, by

whom and for what purpose, this water-consumptive coal gasification industry

could play havoc with Illinois' water

supply. Citizens must be assured, at the

very least, that their municipal water

supplies will not be interrupted."

One piece of legislation in this vein,

H.B. 1786, was introduced by Rep.

Thaddeus S. Lechowicz (D., Chicago)

during the past legislative session as a

result of the commission's study to

establish a system of registration and

permits for large uses of water. The

measure, which was sent to the Study

Calendar on Counties and Townships

— where it stayed — would have created

the Illinois Water Resources Authority.

Similar legislation is being drawn up in the Illinois Division of Waterways.

"Coal gasification has long been a

concern to us," commented Bruce

Barker of the division. "It's kind of a

double-edged sword with regard to

water supply. We need the water for

energy production, but one coal gasification plant would use water like the

whole city of Rockford or Peoria."

In addition to allocating water based

on supply, he says a permit type statute

applied on an area-by-area basis would

help the state to direct large-scale users

to regions of adequate supply. And, by

rationing the naturally available stream

flow, he believes industry will continue

to augment Illinois' water supply with

reservoirs. "We're really trying to

prevent any cutthroat competition with

this permit system. We want people to

realize the effect their water usage has

on their neighbors." The division's

legislation would differ from H.B. 1786

primarily in that existing agencies

would administer the program.

Glen of the BED predicts that such

legislation will be law in three to five

years. "There is need for a system of

permits for water usage. Communities

need to be able to plan for their water

needs. This will institute a kind of 100-year growth limit to assure a reassessment of needs."

Agricultural land

Illinois South Project members believe that the impact of a widespread

gasification industry on agricultural

land in the state should also be assessed.

They point out that Illinois, the nation's

leading agricultural exporter, is losing

farmland at the rate of about 100,000

acres per year, according to an Illinois

Department of Agriculture estimate.

"New coal mines — both deep mines

and strip mines — along with a coal

gasification industry, including the

possible construction of new reservoirs, pose a quiet, but potentially severe

threat to agricultural lands," Ostendorf

said. "One high energy plant would

require disposal of about 5,000 tons of

solid wastes each day. If used as land fill,

this would require 1,250 acres of land

covered to a depth of 10 feet over the 20

year life of the plant."

One nonprofit energy research organization, the Environmental Policy

Institute (EPI), based in Washington,

D.C, claims that Illinois strip mine laws

both directly and indirectly encourage

the loss of farmland, and that 5,000 to

6,000 acres of farmland are lost to strip

mining in Illinois annually. In a recent

report, "Strip Mining in the Corn Belt,"

the EPI says the Illinois Mined Land

Conservation and Reclamation Act and

Rule 1104 encourages this loss due to

the absence of any provision for determining pre-mining agricultural productivity or yield. "There are serious

questions as to whether high capability

agricultural lands strip mined for coal

can be returned to their original capabilities within an acceptable period of

time." It can take 10 to 30 years to

restructure agricultural soil after strip

mining, researchers say.

The loss of farmland can be lessened

through the use of deep mining, however, the report states. "There is more

deep-minable coal in four Illinois

counties — Jefferson, Macoupin,

Montgomery and Sangamon (22.3

billion tons) — than there is strippable

coal in the entire state (19.5 billion tons).

In fact, there is more deep-minable coal

in Illinois than there is strippable coal in

the entire nation." In regard to Illinois'

importance as an agricultural state, the

report adds, "As of 1975, Illinois accounted for 15 per cent of the nation's

export shares for feed grains and feed

products, ranking second in the nation,

and 16 per cent of the nation's export

shares of soybeans and soybean products, ranking first in the nation." Illinois

South Project members and others

concerned about the growth of the coal

conversion industry believe Illinois

citizens have not had a great deal of

influence to date on governmental

decisions which are accelerating what is

termed "the new coal boom." Ostendorf concludes, "If citizens are to have

any voice concerning the siting and

development of new plants, they must

work quickly to recapture their role in governmental decision-making processes."

20 / November 1976 / Illinois Issues