|

Home | Search | Browse | About IPO | Staff | Links |

|

Home | Search | Browse | About IPO | Staff | Links |

|

Sterling Park District project

By Frank Duis,

Director of Parks and Recreation Due to the rising cost of natural gas and electricity throughout the country, park and recreation departments with facilities must look to alternative forms of energy, if, in fact, they intend to exist and provide needed programs for the public in these facilities. It is a known fact that swimming pools, both indoor and outdoor, account for the largest portion of solar applications in the world today. Due to restriction placed on natural gas and electricity by several states, solar energy and its counterpart, wind energy, are the keys to keeping our facilities open to the public. Background on Sterling Park District Recreation Center Project The Sterling Park District Recreation Center has 29,202 square feet of space and a total volume of 657,500 cubic feet. The building houses a 42' x 75' pool and a 32' x 33' diving well along with a 96' x 107' gymasium used for basketball, volleyball, tennis and other general purpose uses. The unique thing about the Sterling Park District Recreation Center, which went into operation April 5, 1970, is that it possesses a corten steel mansard roof which over the years has rusted, turning a dark blue color. The southern exposure of this mansard roof measures 243' long and 17 1/2' high and has great absorptivity. With the conduction factor of the dark corten steel and the undisturbed southern exposure, the Sterling Park District pursued the idea of testing the theory of a trickle-type solar collection system using this roof

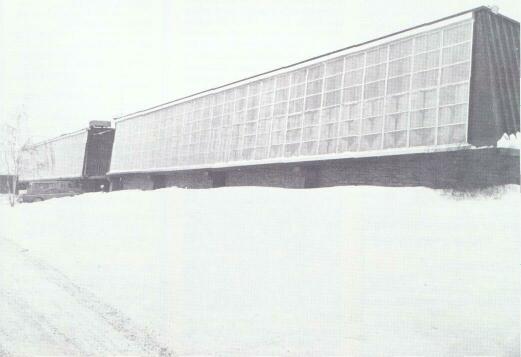

An overall view of the southern exposure of the Sterling Park District Recreation Center solar collection system. The solar collection system measures 17'x 216', using 110 - 4' x 7' panels utilizing filon and tedlar glazing. Illinois Parks and Recreation 20 May/June 1982 assembly. In August of 1979 a simple solar test panel utilizing pool water from the filter pump to a header system on the mansard roof, was installed. Using clear visqueen as a panel cover for the trickle collector, an increase of between 4° and 8° was derived returning to the filter system. Accurate records of the test experiment were kept, and the data received served as a basis for the grant application. When the Sterling Park District Recreation Center was built, the cost of natural gas was 17c a therm. Today that cost has risen to 35c a therm. With the inflated cost and a usage of 189 therms a day, it was decided to pursue state and federal assistance with the project, especially since on-site date indicating a sound solar application was available. The Sterling Park District sought the assistance of Milton Costello, P.E., of Amityville, New York, who had varied experience in the swimming pool and solar field. Costello designed an active liquid solar system which is the first of its kind, retrofitted to an existing building. The basic collect system employs 216' x 17 1/2', a total of 3,780 square feet of solar collectors on the south mansard roof. These collectors are 4' x 7', doublefaced, using tedlar and filon as the plate. Prior to the collectors being installed the mansard roof was sandblasted and coated with a black absorber paint. The 216' of header pipe with nozzles sprays the water down the mansard to the collection trough. The 110 solar collector panels transfer the heat energy by convection, serving as a base for the system. How the System Operates The system utilizes four pumps and a Westinghouse templifier heat pump with a capacity of 216,000 Btu's per hour. This liquid-to-liquid heat pump is actually an absorption chiller returning the water to the twin pool complex and shower room facilities. Solar Collector System Pump The solar collector pump suction is located downstream from the swimming pool hair strainer. This 71/2 hp pump forces 300 gallons per minute of pool water to a 6" pvc distribution header at the roof line of the Recreation Center south mansard corten steel roof. The water is distributed by 440, 1/2" pvc nipples, through 3/16" holes drilled in the cap of each nipple. The water trickles down a distance of 17' behind the solar collector panels, picking up heat as it falls. The water is collected in the existing building gutter and returned to the swimming pool filter tank through an insulated 6" pvc underground piping system. The water is returned to the pool proper by the pool filter pump. The collected heat is stored, or held, in the twin swimming pool complex itself. The process continues as long as solar radiation is available and until such time as the pool water temperature has risen to between 5° and 6°. Each 1,000 gallons of pool water will then have stored about 50,000 Btu's. Illinois Parks and Recreation 21 May/June 1982

Source Water Pump The source water pump takes pool water from the same point as the solar collector pump. The pump provides 57 1/2 gallons per minute to the evaporator heat exchanger of the Westinghouse templifier heat pump. Heat is extracted from the pool water by the evaporation of a special freon mixture (R-114) in the heat exchanger. The pool water is cooled to about 7° by the heat extraction and is returned to the pool via the pool filter tank and pump. The maximum heat extraction is 216,000 Btu's per hour. Hot Water Circulation Pump The hot water circulating pump takes water from the hot water storage tank which is located behind the Recreation Center and forces it through the Westing-house templifier heat pump condenser. This water picks up heat from the heat rejection side of the heat pump cycle and is returned to the hot water storage tank which is heavily insulated. The cycle continues until the water storage tank temperature is 180°. Three conditions must be met before the heat pump system will operate. They are: 1) the twin swimming pools must have stored heat available for extraction; 2) the hot water storage tank must be below the maximum water temperature of 180°; and 3) the off-peak electric rate must be in effect. This is set by a 24 hour, 7 day clock program control. The Domestic Water Pump The domestic water pump supplies hot water to the Recreation Center shower room facilities. It pulls water from the hot water storage tank and supplies it to the inlet of the present gas water heater through a system of check valves. This pump is energized by a flow switch installed on the domestic hot water supply header. Water pumped from the storage tank is replaced automatically by a float control and selenoid valve makeup system. The existing gas-fired hot water heater becomes a backup system for the solar hot water installation. It will only kick in when necessary to top off water supplied from the solar hot water storage tank.

Computer System In an effort to record the effectiveness of the Sterling Park District Solar Hot Water Heating System Project and provide data for agencies, the Sterling Park District installed a TRS-80 Model III computer with a line printer to monitor the system in operation. Project Engineer Milton Costello installed special thermocouples in the piping system wired to the central office and through digital readout instruments, temperatures are recorded with this data fed to the computer system to monitor the effectiveness of the entire project. Sterling Park District officials will make this information available to responsible individuals and agencies. Tours of the facility to see the system in operation will also be available to further demonstrate the effectiveness of a trickle-type solar collection system retrofitted to an existing building. The expected savings on the project will be 89 therms a day from the now 189 therms being expended for heat energy. The net cost reduction to the Sterling Park District's heating bill at the Recreation Center will be in the neighborhood of $11,000.00 a year. The major existing conventional energy system blends in with the solar collection system in that it is a natural gas hot water system pumped through air handling heat exchangers located throughout the facility. The project was funded under a 100°/o grant from the Illinois Institute of Natural Resources in Springfield, Illinois and the Department of Energy in Argonne, Illinois. The total cost of the project was $140,170.00. Eighty per cent (80%) of the funding came from the Illinois Institute of Natural Resources ($109,736.00) and the remaining twenty per cent (20%) funding ($30,434.00) from the Department of Energy's Midwest Appropriate Technology Small Grants Program. Illinois Parks and Recreation 22 May/June 1982 |

|

|